- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

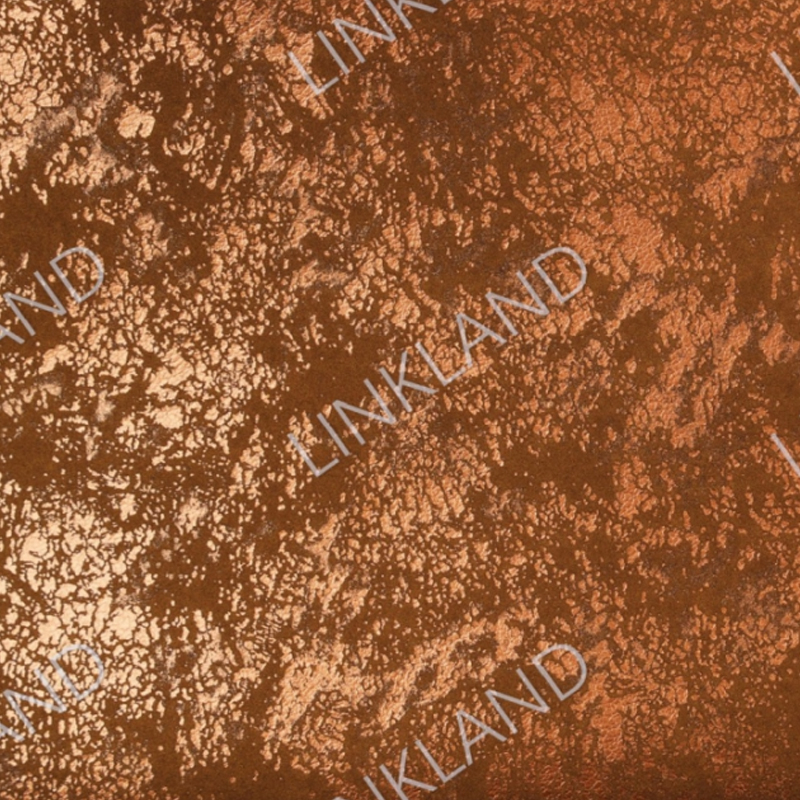

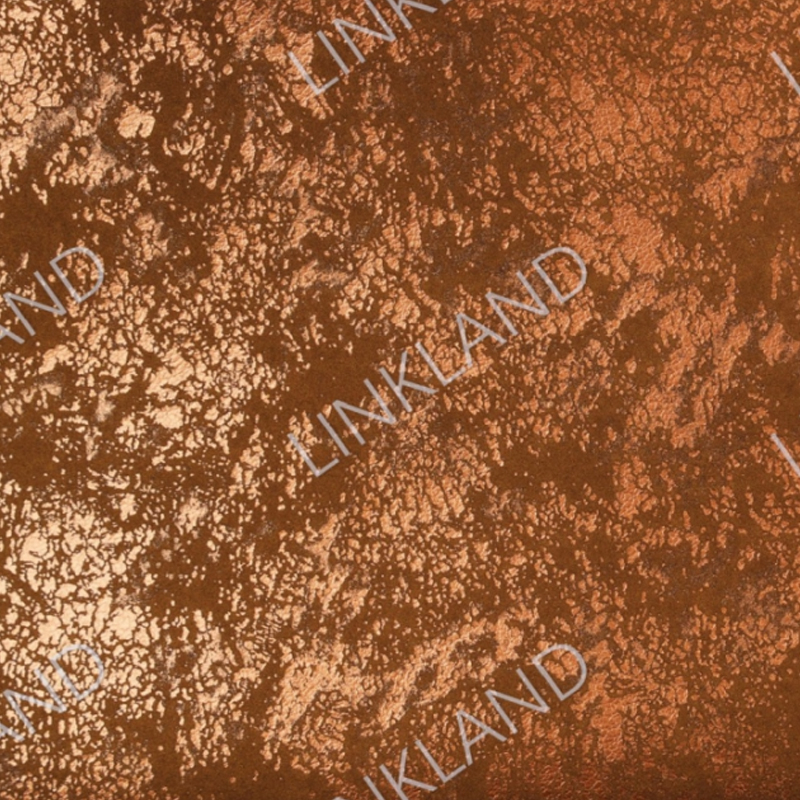

The LK-R227G Die-Cutting Release Paper features a coated release surface with a distinctive textured pattern, providing superior release performance during die-cutting and punching processes. This release paper is tailored to meet the needs of industries requiring precision and efficiency, ensuring that the materials pass through cutting and punching operations smoothly, with minimal resistance.

The unique textured pattern reduces friction between the cutting die and material, allowing for clean cuts and precise results. It is designed for a wide range of flexible materials, making it a versatile solution for die-cutting paper, plastic films, adhesive-backed products, and more. Whether you're in the automotive, electronics, or packaging sector, LK-R227G ensures high-quality results in every production run.

Textured Release Surface: The textured pattern significantly reduces friction during die-cutting and punching, ensuring smoother, faster processing.

Superior Release Performance: The coated release surface ensures clean and precise cuts, with minimal adhesion issues, resulting in fewer production interruptions.

Precision Cutting: Delivers high accuracy and precision in die-cutting and punching applications, ensuring clean and consistent results.

| Property | Details |

| Model | LK-R227G |

| Coating Type | Coated release paper |

| Coating Surface | Textured surface for improved friction resistance |

| Temperature Resistance | Up to 300°C |

| Weight | Customizable (typically 80-150gsm) |

| Release Force | Customizable (ranges from 1g to 1000g) |

| Width | Customizable (up to 1090mm) |

| Length | Customizable (up to 5000m per roll) |

| Paper Thickness | Customizable (ranges from 50gsm to 200gsm) |

| Smoothness | High smoothness level, ensuring consistent release properties |

| Tensile Strength | High tensile strength for minimal tear and breakage during use |

| Perforation Strength | High perforation resistance to ensure easy punching and cutting |

| Adhesion Resistance | Excellent adhesion resistance for smooth cutting without material sticking |

| Customization Options | Customization available for size, weight, coating type, release force, and length |

Q1: What makes LK-R227G suitable for die-cutting and punching?

A1: LK-R227G features a textured surface and coated release paper, which greatly reduces friction and adhesion, ensuring smooth die-cutting and punching with high precision.

Q2: How does LK-R227G improve the die-cutting process?

A2: LK-R227G enhances the die-cutting process by reducing friction between the cutting die and the material, which prevents adhesion issues. This results in cleaner cuts, higher precision, and reduced wear and tear on cutting dies, ultimately improving overall production efficiency.

Q3: Can LK-R227G be used for both single-sided and double-sided die-cutting?

A3: Yes, LK-R227G can be used for both single-sided and double-sided die-cutting processes, depending on your specific application. Its versatility in different setups allows it to cater to various production needs.

At Linkland, innovation is at the heart of everything we do. We believe that staying ahead of industry trends and technological advancements is crucial to providing our clients with the most effective and cutting-edge solutions. That's why we place a strong emphasis on continuous investment in research and development (R&D).

Our dedicated R&D team works tirelessly to develop new materials, improve existing products, and explore new applications for our release papers and synthetic leathers. By embracing new technologies and innovations, we ensure that our products not only meet current industry standards but also anticipate future demands. This forward-thinking approach helps our clients stay competitive in their respective markets.

The LK-R227G Die-Cutting Release Paper features a coated release surface with a distinctive textured pattern, providing superior release performance during die-cutting and punching processes. This release paper is tailored to meet the needs of industries requiring precision and efficiency, ensuring that the materials pass through cutting and punching operations smoothly, with minimal resistance.

The unique textured pattern reduces friction between the cutting die and material, allowing for clean cuts and precise results. It is designed for a wide range of flexible materials, making it a versatile solution for die-cutting paper, plastic films, adhesive-backed products, and more. Whether you're in the automotive, electronics, or packaging sector, LK-R227G ensures high-quality results in every production run.

Textured Release Surface: The textured pattern significantly reduces friction during die-cutting and punching, ensuring smoother, faster processing.

Superior Release Performance: The coated release surface ensures clean and precise cuts, with minimal adhesion issues, resulting in fewer production interruptions.

Precision Cutting: Delivers high accuracy and precision in die-cutting and punching applications, ensuring clean and consistent results.

| Property | Details |

| Model | LK-R227G |

| Coating Type | Coated release paper |

| Coating Surface | Textured surface for improved friction resistance |

| Temperature Resistance | Up to 300°C |

| Weight | Customizable (typically 80-150gsm) |

| Release Force | Customizable (ranges from 1g to 1000g) |

| Width | Customizable (up to 1090mm) |

| Length | Customizable (up to 5000m per roll) |

| Paper Thickness | Customizable (ranges from 50gsm to 200gsm) |

| Smoothness | High smoothness level, ensuring consistent release properties |

| Tensile Strength | High tensile strength for minimal tear and breakage during use |

| Perforation Strength | High perforation resistance to ensure easy punching and cutting |

| Adhesion Resistance | Excellent adhesion resistance for smooth cutting without material sticking |

| Customization Options | Customization available for size, weight, coating type, release force, and length |

Q1: What makes LK-R227G suitable for die-cutting and punching?

A1: LK-R227G features a textured surface and coated release paper, which greatly reduces friction and adhesion, ensuring smooth die-cutting and punching with high precision.

Q2: How does LK-R227G improve the die-cutting process?

A2: LK-R227G enhances the die-cutting process by reducing friction between the cutting die and the material, which prevents adhesion issues. This results in cleaner cuts, higher precision, and reduced wear and tear on cutting dies, ultimately improving overall production efficiency.

Q3: Can LK-R227G be used for both single-sided and double-sided die-cutting?

A3: Yes, LK-R227G can be used for both single-sided and double-sided die-cutting processes, depending on your specific application. Its versatility in different setups allows it to cater to various production needs.

At Linkland, innovation is at the heart of everything we do. We believe that staying ahead of industry trends and technological advancements is crucial to providing our clients with the most effective and cutting-edge solutions. That's why we place a strong emphasis on continuous investment in research and development (R&D).

Our dedicated R&D team works tirelessly to develop new materials, improve existing products, and explore new applications for our release papers and synthetic leathers. By embracing new technologies and innovations, we ensure that our products not only meet current industry standards but also anticipate future demands. This forward-thinking approach helps our clients stay competitive in their respective markets.